- Home Page

- Company Profile

-

Our Product and Services

- Metal Mesh Products

- Fabrication Services

- Customised Solution

- Mosquito Net

- GI Fencing Wire

- GI Wire Mesh

- Perforated Tray

- Wire Rope

- SS Strip

- SS Tube

- Wire Screens

- Industrial Belts

- Perforated Wire Mesh

- Aluminum Sheets

- Metal Perforated Wire Mesh

- Perforated Sheets

- MS Perforated Sheet

- Mild Steel Perforated Sheet

- GI Perforated Sheet

- Alluminium Perforated Sheet

- SS Perforated Sheet

- Inconel Perforated Sheet

- Brass Perforated Sheet

- Circle Perforated Sheet

- Stainless Steel Perforated Sheet

- Galvanized Perforated Sheet

- Perforated Sheet For Industrial

- Decorative Perforated Sheets For Industrial

- Round Stainless Steel Fine Hole Perforated Sheets For Industrial

- GI Perforated Sheets

- Industrial Perforated Sheets

- Monel Perforated Sheets For Industrial

- SS CRC Perforated Sheets

- Perforated Sheets

- Perforated Metal Sheet

- Metal Perforated Sheets

- Stainless Steel Perforated Sheets

- Copper Perforated Sheet

- Mild Steel Perforated Sheets For Industrial

- SS Perforated Metal Sheets

- Stainless Steel SS Perforated Sheets

- Stainless Steel SS Perforated Sheets For Industrial

- MS Perforated Sheets

- Brass Perforated Sheets

- Rectangular Titanium Perforated Sheets

- Perforated Coils

- Hole Perforated Sheets

- Perforated Circles

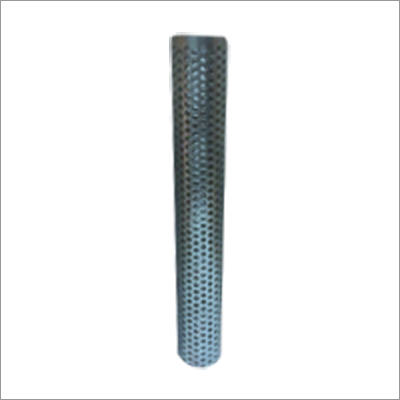

- Perforated Tubes

- Metal Perforated Coils

- Contact Us

SS Strips Tube

100 INR/Square Foot

Product Details:

- Diameter Custom as per requirement

- Coating Type Uncoated / Can be customized

- Recyclable Yes

- Size Customized Sizes

- Product Form Tube Strip

- Tensile Strength 520-750 MPa

- Hardness HRB 90 (varies by grade)

- Click to view more

X

SS Strips Tube Price And Quantity

- 100 INR/Square Foot

- 100 Square Foot

- Non-magnetic (Austenitic grades), Magnetic (Martensitic/Ferritic grades)

- As per order requirement

- Cutting, Slitting, Surface Treatment, Custom Fabrication

- Standard Export Packing, Wooden Boxes/Pallets

- Typically 7-30 Days

- 7.93 g/cm³ (for 304SS)

- Annealed, Pickled, Polished

- 1400-1450°C

- Excellent

- More than 40% (typical for 304SS)

- Plain, Slit Edge, or Custom

SS Strips Tube Product Specifications

- Silver

- Yes

- 0.2mm to 6mm

- As per dimension and thickness

- ASTM, AISI, DIN, EN, GB, JIS

- Strip Tube

- Cr: 18-20%, Ni: 8-12%, others as per grade

- Industrial, Construction, Fabrication, Automobile, Machinery Parts

- Round / Strip / Customized

- Polished / Mirror / Matte / Custom

- Yes

- Manufacturing, Construction, Automotive, Engineering

- 304, 316, etc.

- Yes

- Customized Sizes

- 520-750 MPa

- Bright, Polished, Annealed, Mirror Finish

- Tube Strip

- HRB 90 (varies by grade)

- Custom as per requirement

- Uncoated / Can be customized

- Standard Stainless Steel Alloys

- Customizable; Commonly available in width 5mm to 200mm, Length as required

- 201, 202, 304, 304L, 316, 316L, 410, 420 as per requirement

- Stainless Steel

- SS Strips Tube

- Non-magnetic (Austenitic grades), Magnetic (Martensitic/Ferritic grades)

- As per order requirement

- Cutting, Slitting, Surface Treatment, Custom Fabrication

- Standard Export Packing, Wooden Boxes/Pallets

- Typically 7-30 Days

- 7.93 g/cm³ (for 304SS)

- Annealed, Pickled, Polished

- 1400-1450°C

- Excellent

- More than 40% (typical for 304SS)

- Plain, Slit Edge, or Custom

SS Strips Tube Trade Information

- 15 Days

- Australia, Central America, South America, Western Europe, Middle East, Eastern Europe, Asia, North America, Africa

Product Description

SS strips tube is a type of tubing made from stainless steel strips that have been formed into a tube shape. Stainless steel is a corrosion-resistant material that is strong, durable, and has a long lifespan, making it a popular choice for many different applications.

The strips are typically formed into a tube shape using a tube mill, which uses a series of rollers to bend and shape the strips into a tube. The tube is then welded along the seam to create a continuous, smooth surface.

SS strips tubes are commonly used in a range of applications, including construction, automotive, and manufacturing. They are known for their strength, durability, and resistance to corrosion, making them suitable for use in harsh environments.

The tubes are available in a range of sizes and thicknesses, and can be customized to meet specific requirements. They can also be polished or coated with a range of materials to provide additional protection or improve their appearance.

| Material | SS, MS, Galvanized Steel, Aluminum, Brass, Monel, Inconel, Titanium, Hastelloy, Duplex, Super Duplex |

| OEM Service | Yes |

| Drilling for Heavy Thickness Sheet | 10 to 100 mm |

| Holes Type | Round, Square, Oblong, Rectangular, Capsule, Hexagonal, Dimpled, Lipped |

| Punching Type | Conventional & CNC Type |

| Thickness | 10 mm |

Versatility in Design and Specifications

Our SS Strips Tubes are engineered to suit a wide range of industrial requirements, thanks to customizable thickness, width, length, and edge options. Available in various stainless steel grades, such as 304 and 316, these tubes can be tailored for specific performance needs, ensuring a perfect fit across diverse applications-from construction frameworks to automotive parts.

Superior Material Performance

Made from top-quality stainless steel, these tubes exhibit excellent weldability, non-magnetic or magnetic characteristics depending on grade, and impressive mechanical properties like high tensile strength (520-750 MPa) and more than 40% elongation for 304SS. They also display outstanding resistance to corrosion and heat (up to 870C), ensuring durability in challenging environments.

Professional Finishing and Processing

Our SS Strips Tubes come in a variety of finishes, including polished, annealed, bright, and mirror, and can be delivered in annealed, pickled, or polished conditions as required. Value-added services such as cutting, slitting, surface treatment, and custom fabrication further enhance the product's suitability for specialized projects.

FAQ's of SS Strips Tube:

Q: How are the SS Strips Tubes typically used in industrial and construction applications?

A: SS Strips Tubes are frequently used in manufacturing, construction, automotive, and engineering sectors for structural framing, fabrication of parts, automotive components, and machinery. Their customizable sizes and finishes make them suitable for a wide array of custom industrial and infrastructure projects.Q: What are the available edge types and how do I choose the right one for my application?

A: The available edge types are plain, slit, or custom as per specification. The choice depends on your application's requirements for safety, aesthetics, and fabrication processes. Our team can assist in determining the best edge type for your needs.Q: When can I expect delivery after placing an order for SS Strips Tubes?

A: Lead time for SS Strips Tube orders typically ranges from 7 to 30 days, depending on order size, customization, and processing requirements. Precise timelines are confirmed after evaluation of your specific order details.Q: Where are the SS Strips Tubes manufactured and exported from?

A: All SS Strips Tubes are manufactured and exported from India by experienced manufacturers and suppliers, complying with leading global standards like ASTM, AISI, DIN, EN, GB, and JIS.Q: What is the process involved in customizing SS Strips Tubes?

A: Customization involves selecting the required grade, thickness, width, length, edge type, finish, and surface treatment. Additional processing services such as cutting, slitting, and fabrication are available to match client specifications. Our production team ensures all processes meet quality standards.Q: What are the benefits of using stainless steel strip tubes compared to other materials?

A: Stainless steel strip tubes offer exceptional corrosion and heat resistance, high mechanical strength, excellent elongation (especially for 304SS), and superior surface finishes. Their recyclable nature and customizable attributes make them a preferred choice for long-term industrial and construction use.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese